Txo cov nqi thiab txhim kho kev ua tau zoo yog qhov tseem ceeb ntawm kev ntim khoom lub neej. Raws li ib tug kws muab kev pab ntawmntim tshuab kev daws teeb meem, tswj cov nqi ntim khoom yog qhov tseem ceeb ntawm kev tswj cov khoom. Ntawm no, peb tshawb nrhiav cov tswv yim zoo tshaj plaws rau kev txo nqi hauv kev ntim khoom, categorized rau ntau qhov tseem ceeb rau kev siv.

1. Txo cov nqi khoom siv

Ib qho tseem ceeb ntawm kev txiav cov nqi hauv kev ntim khoom yog los ntawm kev hloov cov khoom siv. Qhov no tuaj yeem ua tiav hauv ntau txoj hauv kev:

Kev hloov khoom siv

- Hloov mus rau cov khoom pheej yig dua: Hloov cov ntaub ntawv kim nrog lwm qhov pheej yig dua tuaj yeem txo cov nqi. Piv txwv li, hloov cov duab los qhia txawv teb chaws nrog cov khoom siv hauv tsev ua dawb, cov ntawv nyiaj dawb nrog cov duab los qhia dawb, lossis cov ntawv dawb nrog grey-rov qab dawb cardboard.

Txo qhov hnyav

- Cov khoom siv qis qis: Siv cov ntaub ntawv nyias nyias tuaj yeem txo tus nqi. Piv txwv li, hloov los ntawm 350g cardboard mus rau 275g, los yog hloov 250g duplex board nrog 400g ib txheej.

2. Txo cov nqi ntawm cov txheej txheem

Optimizing cov txheej txheem koom nrog hauv kev ntim khoom tuaj yeem ua rau kom txuag tau nyiaj ntau:

Cov txheej txheem luam ntawv

- Hloov los ntawm Kub Stamping rau Printing: Hloov kub stamping nrog kub number case luam ntawv tuaj yeem raug nqi zoo. Piv txwv li, hloov kub kub stamping rau txias ntawv nyiaj stamping los yog tsuas yog luam tawm nrog kub-xim number case.

- Hloov Laminating nrog Txheej: Hloov lamination nrog varnishing tuaj yeem txo cov nqi. Piv txwv li, hloov matte lamination nrog matte varnish, los yog anti-scratch lamination nrog anti-scratch varnish.

Consolidating Moulds

- Ua ke Tuag-txiav thiab embossing: Siv ib qho kev tuag uas ua tau ob qho tib si tuag-txiav thiab embossing tuaj yeem txuag nqi. Qhov no suav nrog kev sib txuas cov embossing thiab txiav cov txheej txheem rau hauv ib qho, yog li txo cov pwm yuav tsum tau ua.

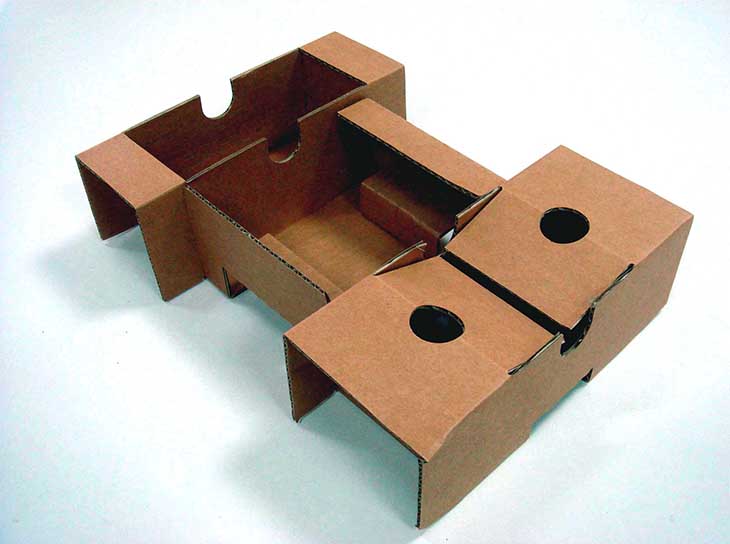

Kev tsim kho kom zoo

- Simplifying Packaging Structure: Streamlining the packing structure can optimize its design for material efficiency and txo nqi tsheb thauj mus los. Simplifying complex ntim tsim kom siv cov khoom tsawg dua tuaj yeem ua tiav lub hom phiaj no.

Siv cov tswv yim txo nqi hauvntim cov qauv tsimMuaj ntau txoj hauv kev uas suav nrog kev hloov khoom siv, kev ua kom zoo dua qub, txo kev siv cov khoom siv, thiab automation. Los ntawm kev tsom mus rau cov ntsiab lus tseem ceeb no, cov tuam txhab tuaj yeem ua tiav cov txiaj ntsig tseem ceeb thaum tswj kev ua haujlwm thiab rov hais dua ntawm lawv cov ntim. Raws li tus kws tshaj lij ntawm kev ntim cov kev daws teeb meem, peb tau cog lus los pab peb cov neeg siv khoom txhim kho lawv cov qauv tsim los txhim kho kev ua tau zoo thiab txo cov nqi. Koom tes nrog peb los tsim cov ntim khoom uas tsis yog tsuas yog ua tau raws li koj xav tau tab sis kuj tseem sawv hauv kev lag luam.

Tiv tauj pebniaj hnub no kom paub ntau ntxiv txog peb cov tswv yim txo nqi hauv kev ntim khoom thiab peb tuaj yeem pab koj ua tiav koj lub hom phiaj ntim khoom kom zoo thiab kev lag luam. Ua ke, peb tuaj yeem tsim cov txheej txheem ntim khoom tshiab uas ua rau muaj qhov sib txawv.

Post lub sij hawm: Jun-22-2024